Share to Mobile

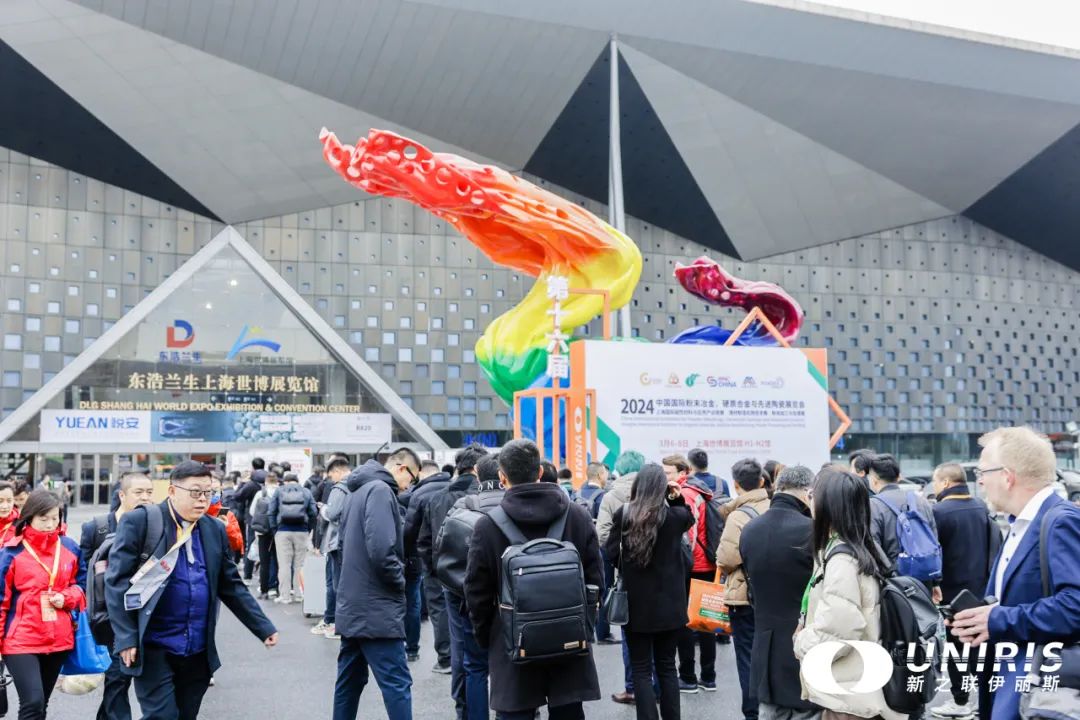

During the 3-day exhibition, a total of 61,308 visitors were received, i.e. 26,883 on the first day, 25,560 the second day, and 8,865 the third day. PM CHINA 2024 has also attracted over 100 professional media partners for field reports, which is featured with dazzling highlights and continuous excitement.

The second exhibition day saw 25,560 visitors Gathering of the Wise, Collision of Thoughts The vibe on site is continuously intensifying Highlights unfolding in waves Work together to bring the exhibition atmosphere to a climax!

26,883 visitors on the first day Gathering nearly 800 global enterprises Comprehensively showcasing the latest products and technologes of 5 relevant industries A convergence in Shanghai of famous experts and industry elites Pooling wisdom, sharing achievements and inspiring innovation Jointly compose a new chapter in industry development!